CHALLENGE

Domino’s Pizza is a global leader in pizza delivery, heavily reliant on digital service and optimization.

After implementing a QR code campaign for Domino’s Pizza and gaining their trust in our solutions, they approached us for comprehensive optimization and modernization of the web and software products used in business management. The central warehouse used Excel, the restaurants operated on software from the parent company, accounting used Azhur, and the company lacked specialized HACCP software for product tracking with a digital dossier. Transferring information between all these systems required a vast amount of manual labor and led to numerous errors and inaccuracies.

SOLUTION

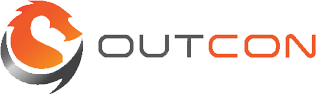

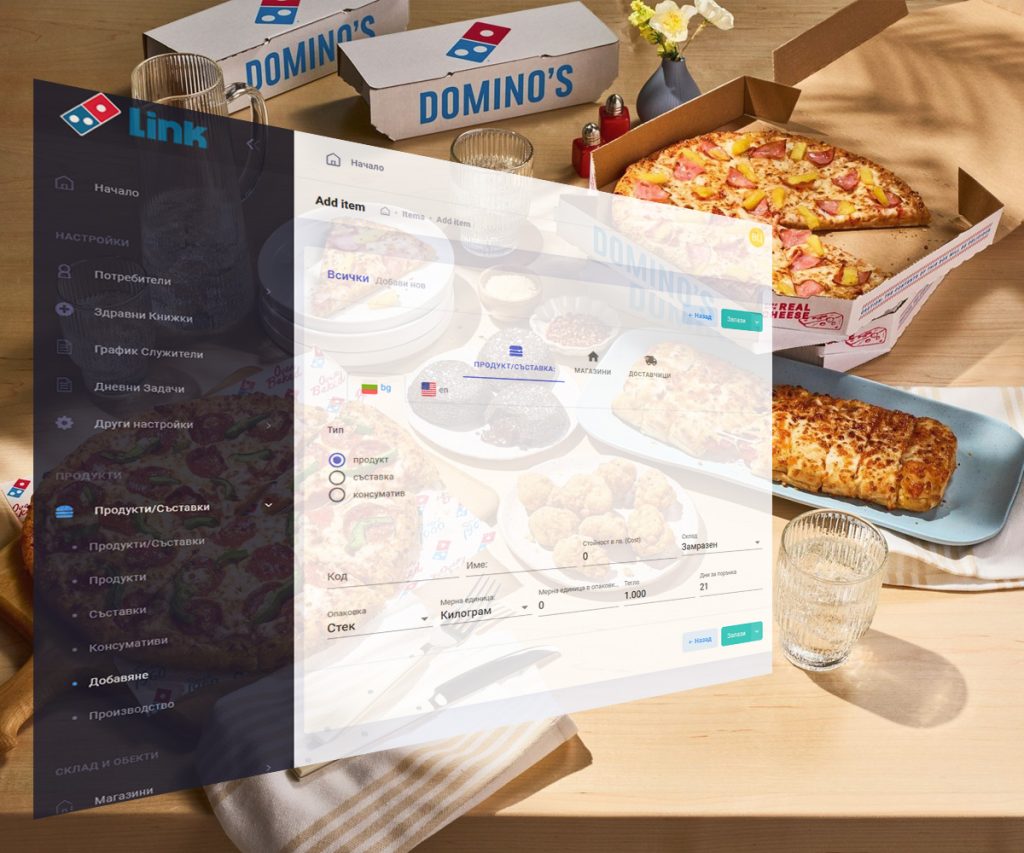

We developed an All-In-One platform that allows different units and employees in the organization to communicate, input data and operations, and eliminated the employees’ interaction with all other software. We added the additional functionalities needed for electronically managing the regulatory required documentation. We introduced multiple levels of control and automated the resolution of operational issues.

We completely eliminated the method of using Excel spreadsheets and emailing them for creating requests to the warehouse, forms, cost calculation, generating waybills, tracking movements between sites, reports to accounting and management, and accountability.

We integrated the parent company’s software into the platform and stopped the direct, uncontrolled, and untraceable access of employees to it by introducing levels of control and confirmation, eliminating the potential for errors and inaccuracy of information entered, and we managed to identify the difficulties employees faced and improve the interface so that all company employees could easily and quickly work with a unified interface.

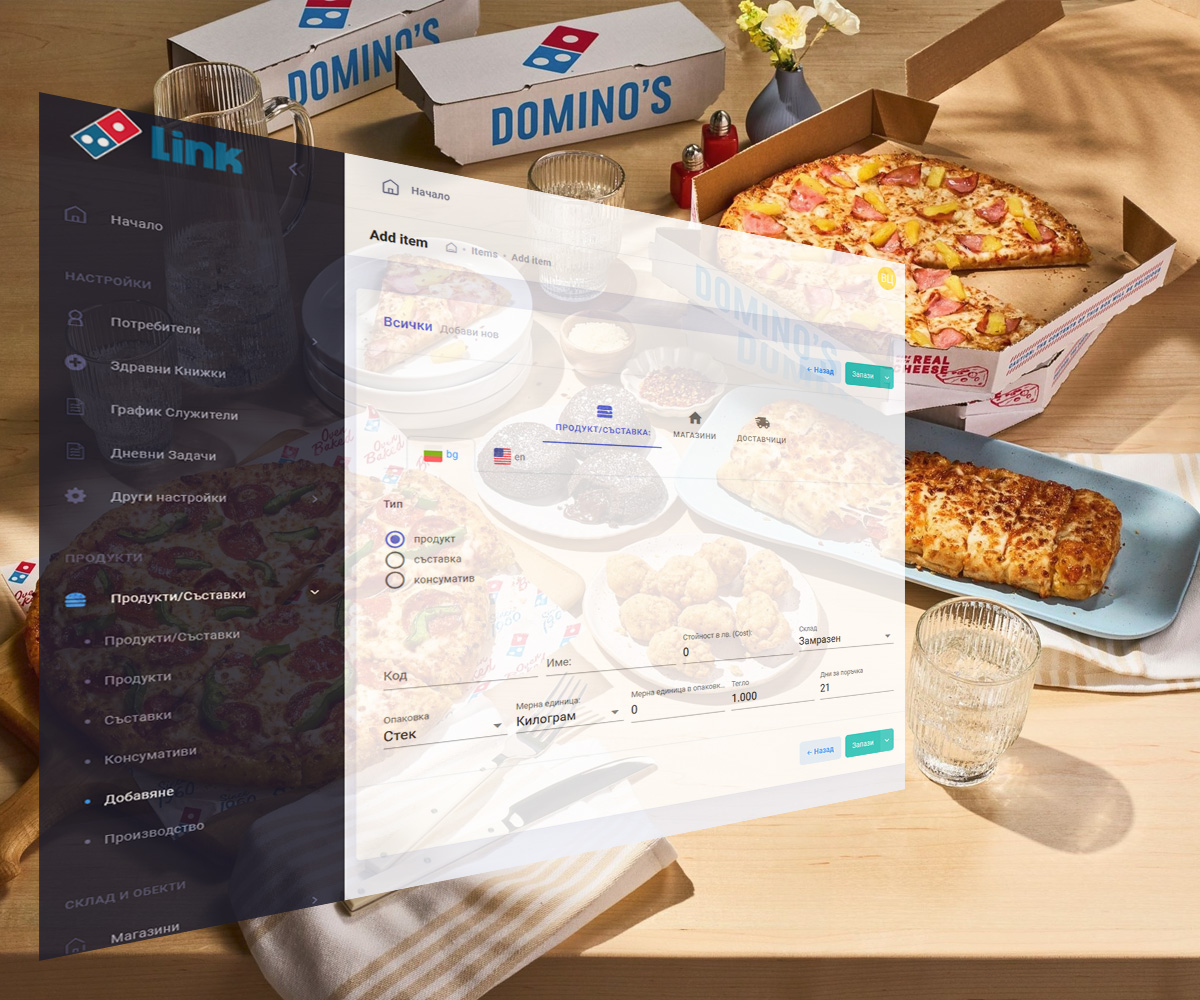

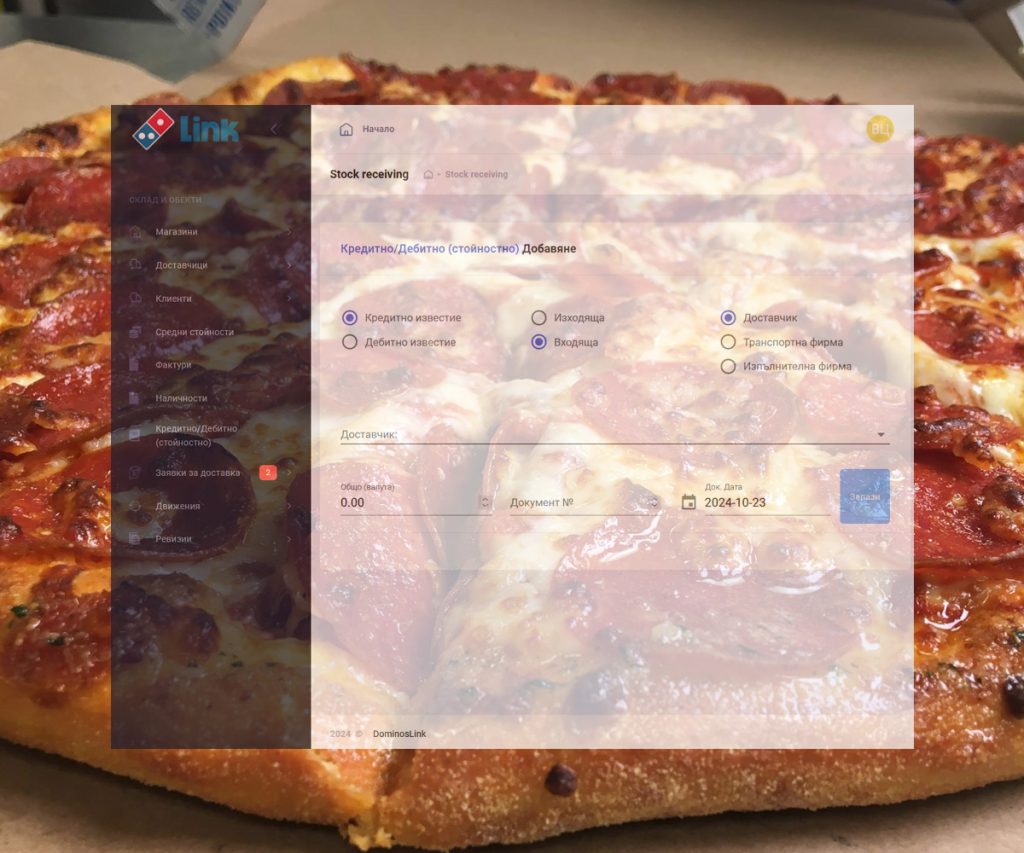

We integrated the accounting software into the platform, which is now used only for generating accounting reports and reports, without the need for any manual data entry and external reports. We process customs declarations, invoices in different currencies, debit and credit notices, discounts for accumulated turnovers to suppliers against average prices, cost of production and materials used, and many other components that are submitted automatically to the accounting software for automatic accounting.

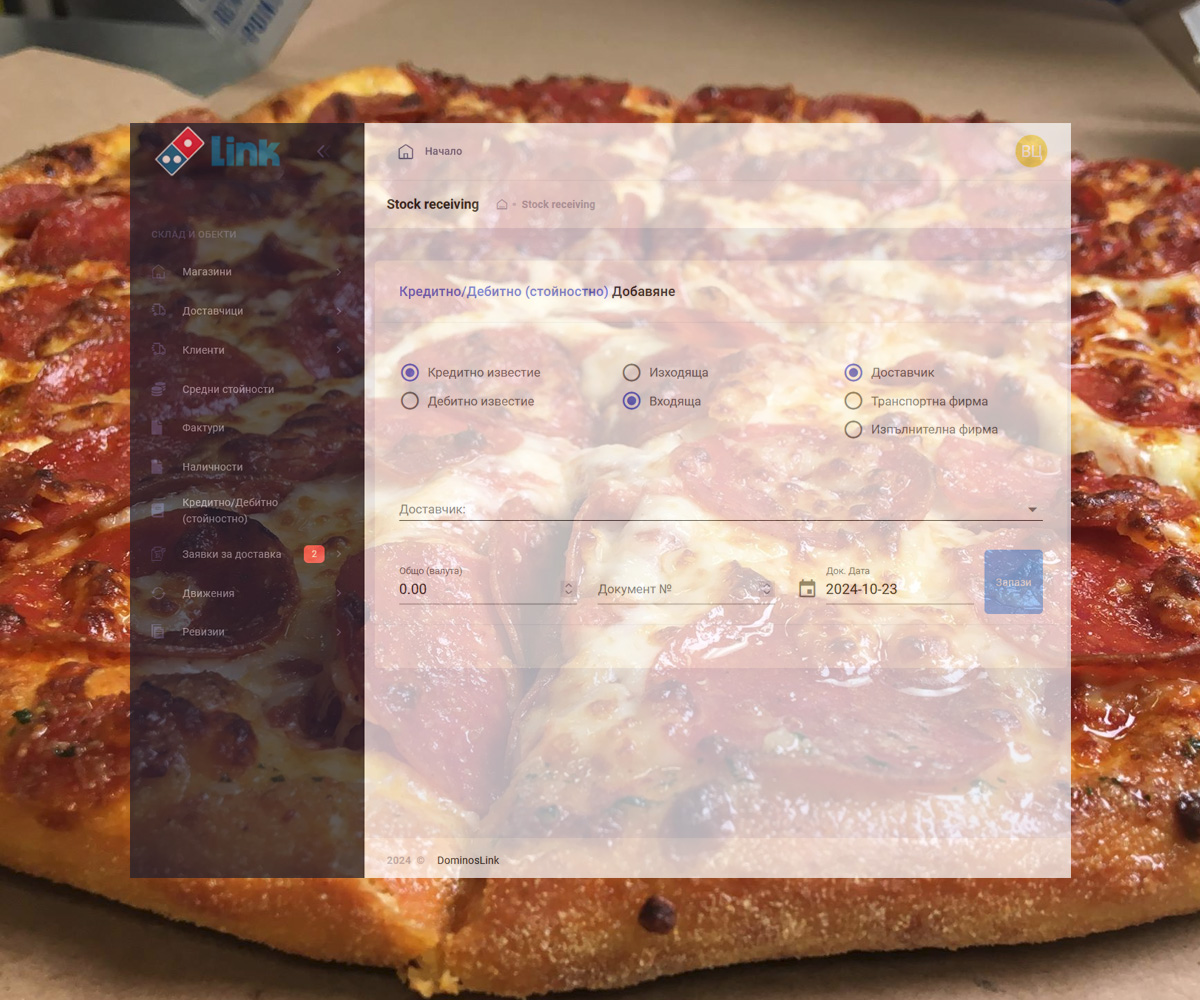

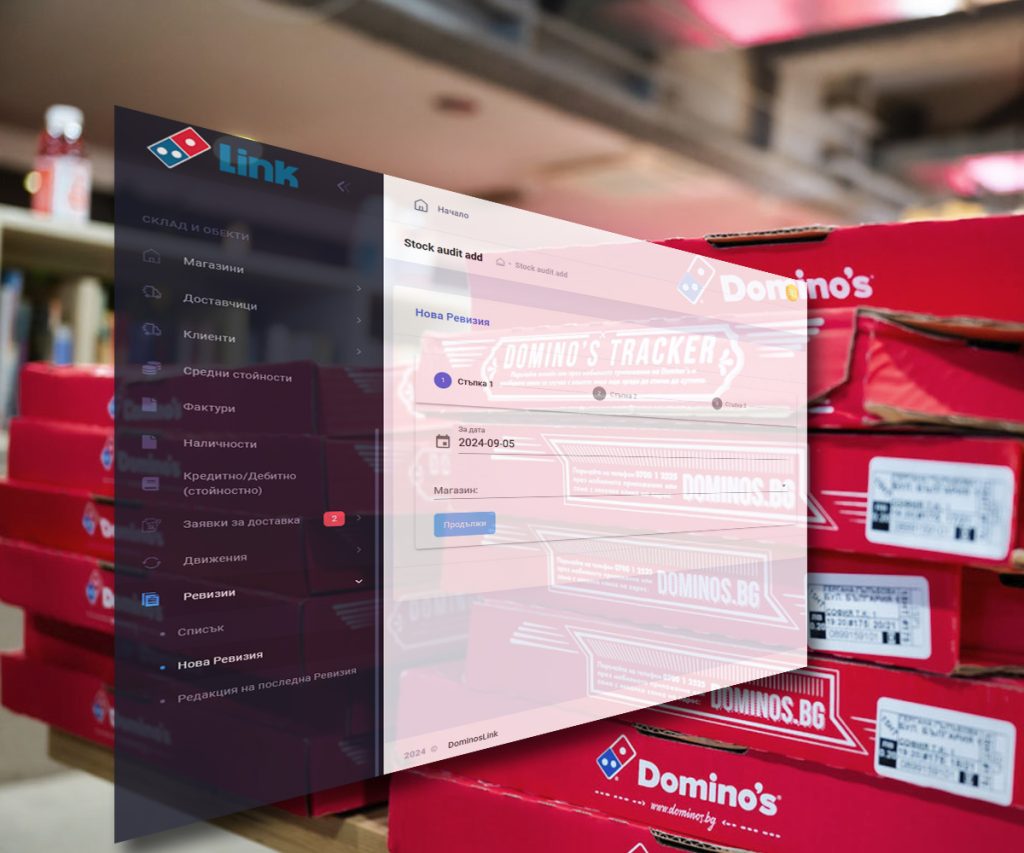

We added a HACCP system to the platform, which tracks batches and expiration dates for each product from its delivery to the central warehouse, distribution to sites, movements between sites, and incorporation into sold foods, as well as scrap, expenses for tests, etc. We also created and added an electronic system for tracking and quality control of various electrical devices and processes and periodic tasks in each site and restaurant, the health status of employees, and an electronic dossier, in accordance with legislative requirements and the food agency.

IMPACT

The solution we created for Domino‘s Pizza digitized and automated a number of processes, significantly reduced the human factor in others, provided multi-level control and automated resolution of issues, and contributed to a significant increase in the quality of service and maintaining proper documentation, in accordance with regulatory provisions, as well as accountability for managerial purposes.

CHALLENGE

Domino’s Pizza is a global leader in pizza delivery, heavily reliant on digital service and optimization.

After implementing a QR code campaign for Domino’s Pizza and gaining their trust in our solutions, they approached us for comprehensive optimization and modernization of the web and software products used in business management. The central warehouse used Excel, the restaurants operated on software from the parent company, accounting used Azhur, and the company lacked specialized HACCP software for product tracking with a digital dossier. Transferring information between all these systems required a vast amount of manual labor and led to numerous errors and inaccuracies.

SOLUTION

We developed an All-In-One platform that allows different units and employees in the organization to communicate, input data and operations, and eliminated the employees’ interaction with all other software. We added the additional functionalities needed for electronically managing the regulatory required documentation. We introduced multiple levels of control and automated the resolution of operational issues.

We completely eliminated the method of using Excel spreadsheets and emailing them for creating requests to the warehouse, forms, cost calculation, generating waybills, tracking movements between sites, reports to accounting and management, and accountability.

We integrated the parent company’s software into the platform and stopped the direct, uncontrolled, and untraceable access of employees to it by introducing levels of control and confirmation, eliminating the potential for errors and inaccuracy of information entered, and we managed to identify the difficulties employees faced and improve the interface so that all company employees could easily and quickly work with a unified interface.

We integrated the accounting software into the platform, which is now used only for generating accounting reports and reports, without the need for any manual data entry and external reports. We process customs declarations, invoices in different currencies, debit and credit notices, discounts for accumulated turnovers to suppliers against average prices, cost of production and materials used, and many other components that are submitted automatically to the accounting software for automatic accounting.

We added a HACCP system to the platform, which tracks batches and expiration dates for each product from its delivery to the central warehouse, distribution to sites, movements between sites, and incorporation into sold foods, as well as scrap, expenses for tests, etc. We also created and added an electronic system for tracking and quality control of various electrical devices and processes and periodic tasks in each site and restaurant, the health status of employees, and an electronic dossier, in accordance with legislative requirements and the food agency.

IMPACT

The solution we created for Domino‘s Pizza digitized and automated a number of processes, significantly reduced the human factor in others, provided multi-level control and automated resolution of issues, and contributed to a significant increase in the quality of service and maintaining proper documentation, in accordance with regulatory provisions, as well as accountability for managerial purposes.